OPENFORM

Practical and high-quality solutions for process planners and tool makers

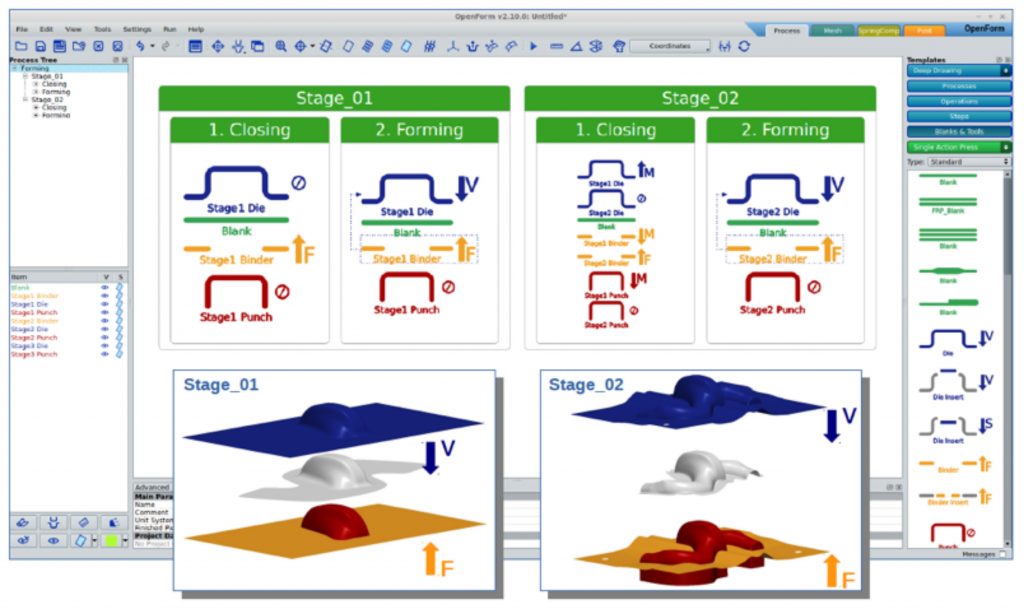

The first universal solver-independent graphical user interface

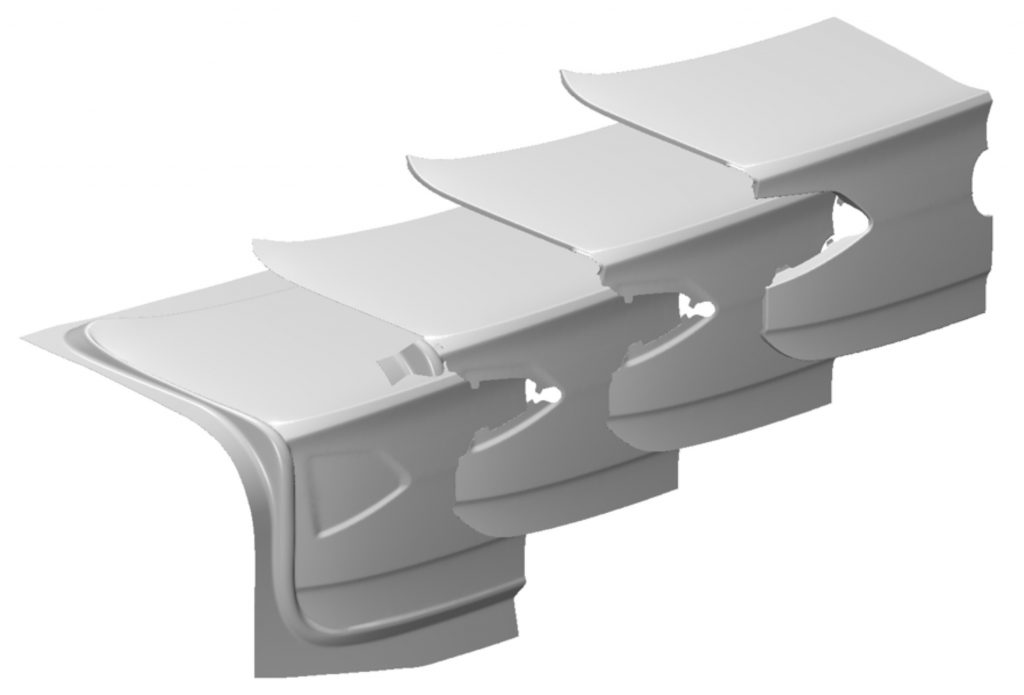

- For the simulation of new and innovative forming processes

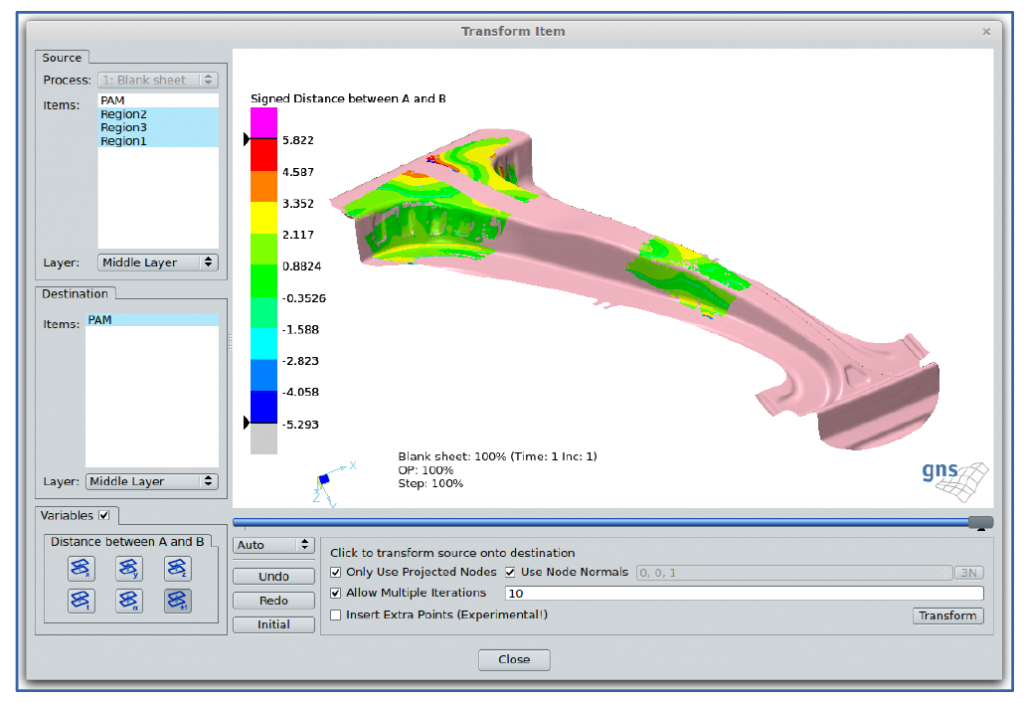

- For the reliable comparison between production and numerical simulation

- For quality control of daily work in design and production

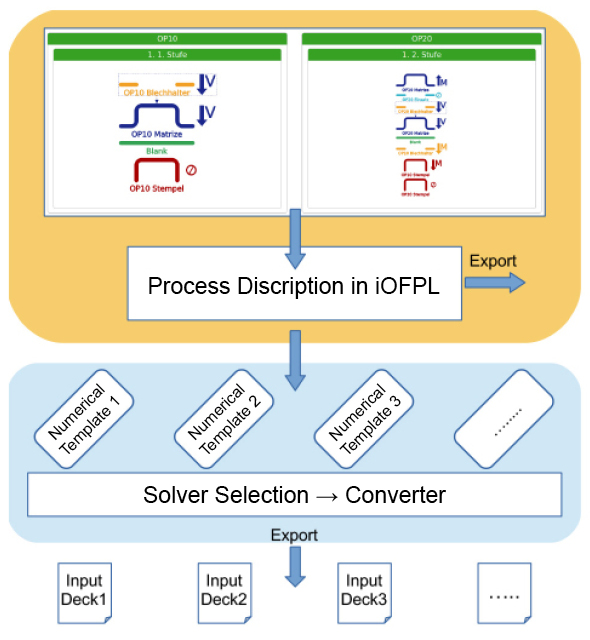

The OpenForm philosophy is based on the unique concept of the open data interface for commercial forming software: this is realized on the one hand through a solver-independent description of the forming process, and on the other hand through a solver-independent evaluation of the results.

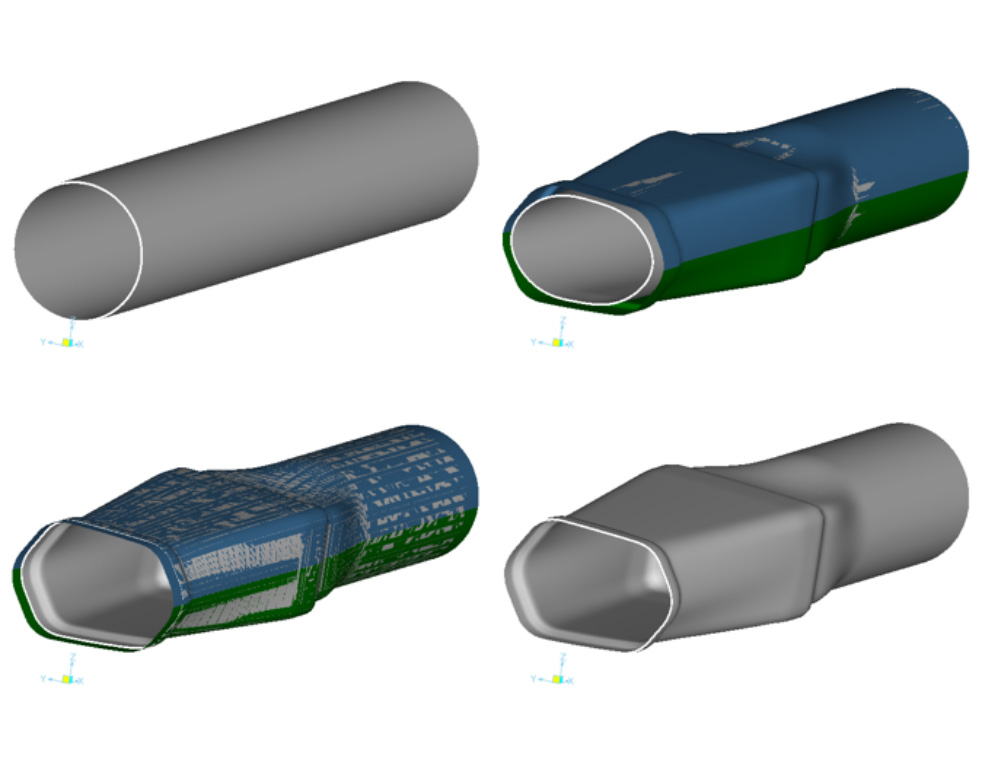

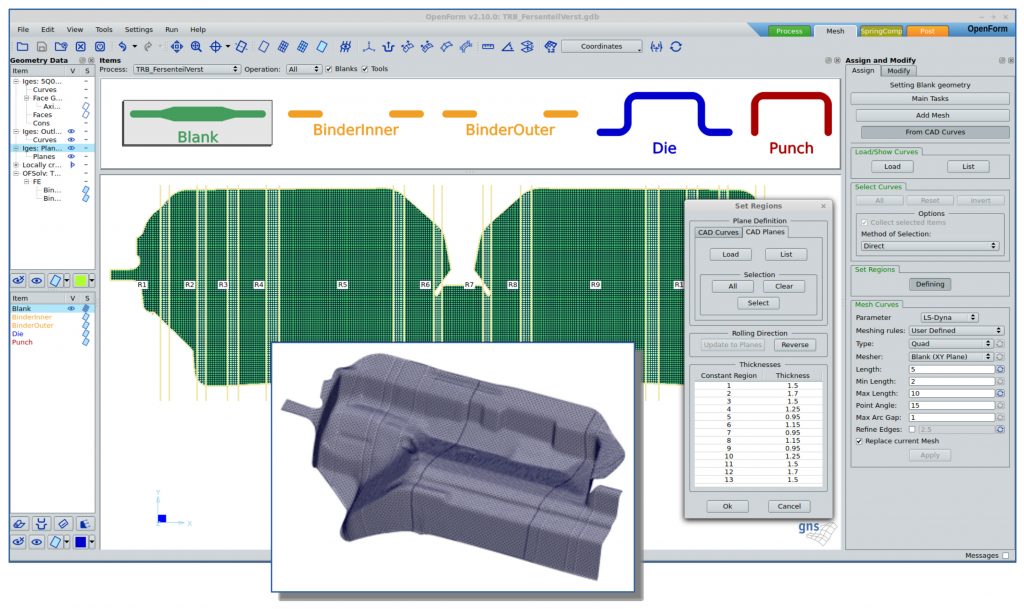

OpenForm is equipped with a powerful mesh generator, which meets the needs of the different solvers. Alongside the actual mesh generation, the user has comprehensive capabilities available for the examination and editing of the CAD geometry and the mesh.

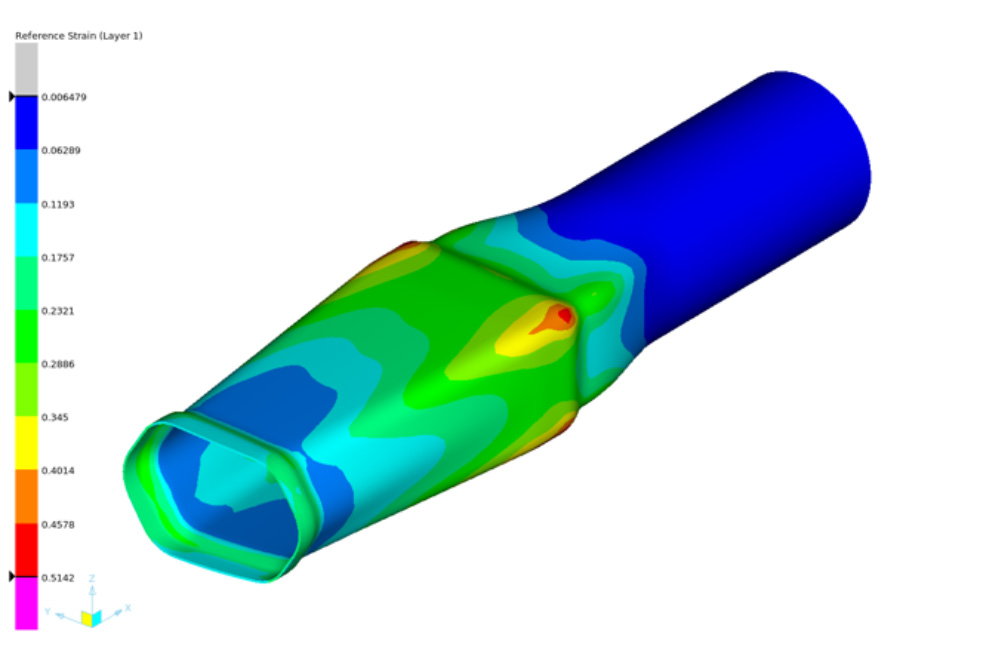

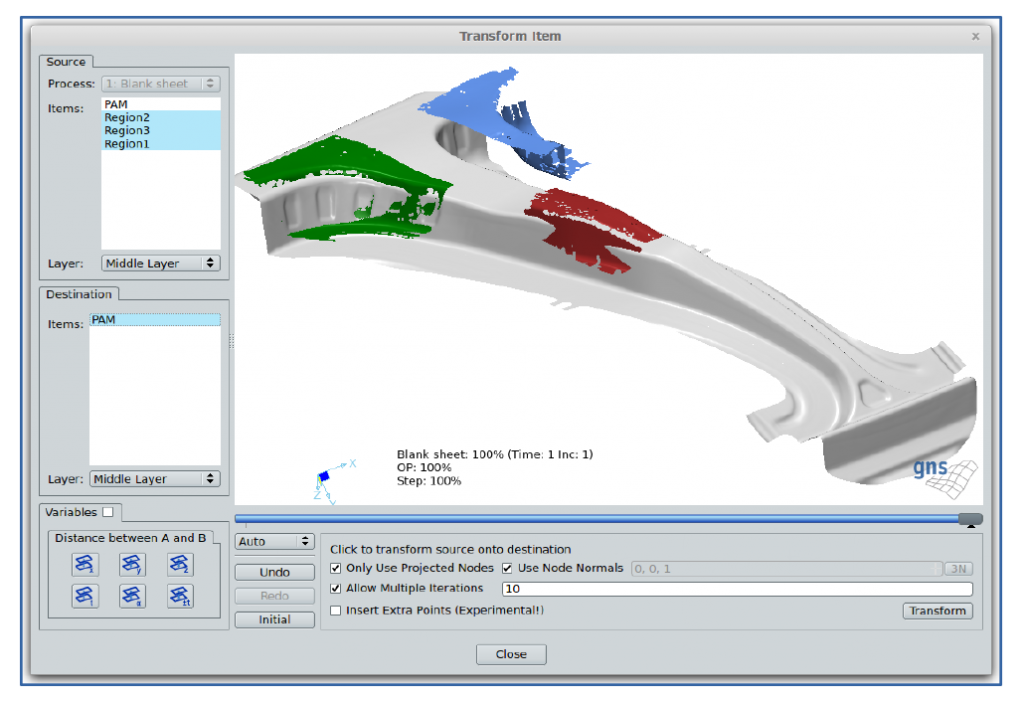

The postprocessing in OpenForm is focused on the user’s daily work requirements: the user interface and the presentation of forming-specific results such as FLD and ZTU diagrams, edge crack or scratch line displays allows even inexperienced users to make practical judgments about the results.

OpenForm is equipped with the integrated Finite Element Solver OFSolv, which is best suited for numerical simulation of the quasi-static cold forming of sheet metal. OFSolv can simulate not only deep drawing and hydroforming but also bending and bonding processes.